The Blackburn Potato Chitting Crate

The potato farmer's practical alternative to potato chitting trays or boxes

Less Handling

Less Labour

Less Damage

Boxing up and stacking in store saves 75% of labour/time. Crates can be stacked 5 high giving a minimum 30% more store capacity compared to seed potato trays.

Inspection and control is easier than with any other known type of chitting container.

The all metal construction is hygienic and cannot carry disease and is ideal for dipping and fogging.

The Blackburn crate is equally suitable for the glasshouse or the controlled environment store, and can be integrated with existing trays or bulk containers.

the advantages of the Blackburn Crate in the field are many, but mainly in the saving of labour and time.

the labour required from the store to the planter hopper can be reduced from 3 men to just 1.

The tonnage safely carried on a trailer is increased.

All potatoes can be poured into the planter hopper with a teleporter with a tippler attachment.

The planter hopper can be refilled more rapidly, enabling the planting of greater acreage. Up to 50% increase has been achieved.

The saving of time in clearing the empty crates from the field is also a factor to be considered.

HOW MUCH TIME ARE YOU WASTING NOW?!

The development of a Bulk Chitting Crate in steel and welded mesh was promoted by suggested from ADAS staff and tests of various shapes were carried out in cooperation with experimental farms. These tests resulted in the present construction. This design is fully patented (No. 1449166).

The side rotating crate design was added later with forklift tine runners along the length of the crate allowing a box rotator to be used.

Improvements in manufacturing techniques have contained the price, such that any price rises have been due to just the increases in the costs of raw materials.

SAVE TIME - SAVE MONEY - AVOID WASTE

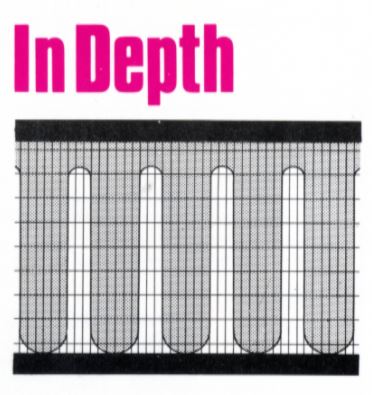

The design of the curved welded mesh interior, ensures that no surface of the potato is any more than 3” from light making inspection and control easier.

Crates can be stacked up to 5 meters high, with unobstructed passage for light penetration and air movement.

Light is essential for chitting, and chitting-lights provide the ideal environment for seed potatoes to sprout ahead of planting. K J Engineering offer both traditional and energy-efficient LED tubes.

<Visit K J Engineering's Website>

Saving time and labour, by using a telehandler fork lift with a tipper attachment, to fill the hopper with minimum damage, increasing acreage.

The 120F Box Rotator - Perfect for Blackburn Potato Chitting Crates (Standard Model)

The Side Tipping Potato Chitting Crate

The Blackburn Potato Chitting Crate is also available as a side tipping model for use with a fork lift truck or telehandler with rotating tines.